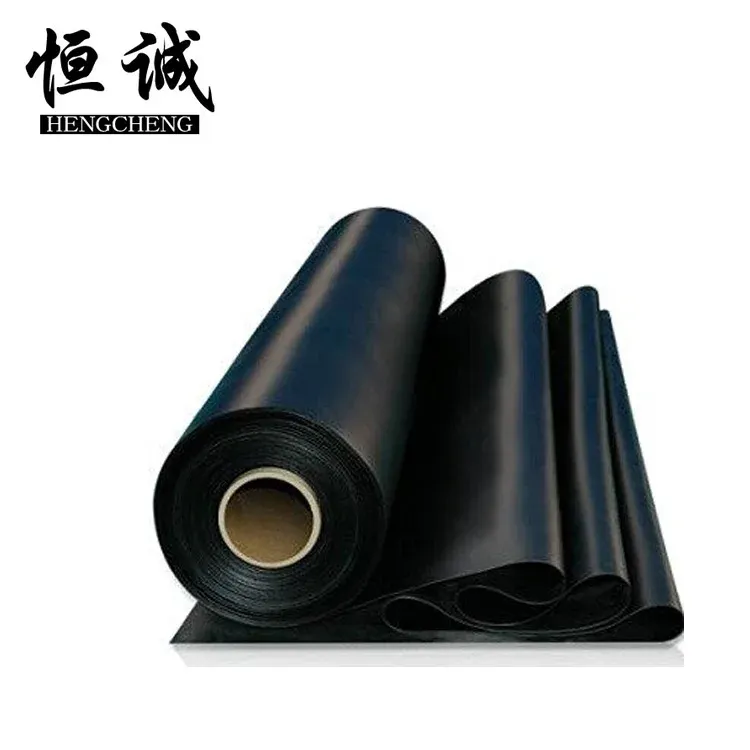

In summary, China seal strip stoppers for doors are an essential addition to any home or business. Their ability to enhance energy efficiency, reduce noise, protect against moisture and dust, and add aesthetic value cannot be understated. When purchasing these products, it is vital to prioritize quality and select reliable manufacturers to ensure long-lasting performance. By investing in quality seal strip stoppers, individuals can enjoy a more comfortable, quieter, and healthier living environment. With the right door seal strip stopper, even the simplest doors can contribute to the overall success of a structure's design and functionality.

Home

Home

Football boots, on the other hand, prioritize lightweight construction and stud patterns for better grip on the field Football boots, on the other hand, prioritize lightweight construction and stud patterns for better grip on the field

Football boots, on the other hand, prioritize lightweight construction and stud patterns for better grip on the field Football boots, on the other hand, prioritize lightweight construction and stud patterns for better grip on the field Modern bootfoot waders come in a variety of colors and patterns, allowing enthusiasts to express their personal style while adhering to camouflage needs Modern bootfoot waders come in a variety of colors and patterns, allowing enthusiasts to express their personal style while adhering to camouflage needs

Modern bootfoot waders come in a variety of colors and patterns, allowing enthusiasts to express their personal style while adhering to camouflage needs Modern bootfoot waders come in a variety of colors and patterns, allowing enthusiasts to express their personal style while adhering to camouflage needs